Nursery seeding machine | Seeder machine | Vegetable seeder machine

Nursery seeding machine | Seeder machine | Vegetable seeder machine

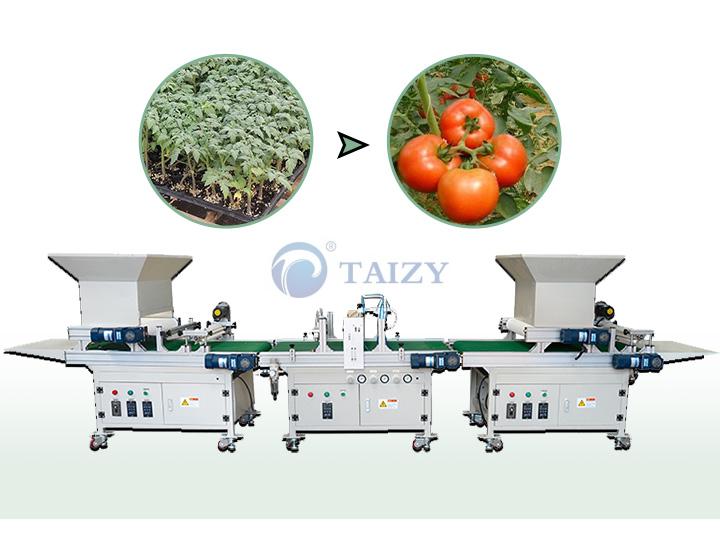

A nursery seeding machine is a device that allows you to plant various vegetable seeds in trays. It helps people with the work of planting seeds. Eventually, these seeds grow into a nursery.

The nursery means cultivating seedlings. It refers to the cultivation of seedlings in nurseries, hotbeds, or greenhouses for transplanting to the ground for planting. It can also refer to the stage in which various organisms undergo artificial protection until they can survive independently. Nursery is a labor-intensive, time-consuming, and highly technical job. If you have a seed sowing machine, you can grow seedlings easily and efficiently.

Definition of nursery seeding machine

A nursery seeding machine is a modern seedling technology that uses light soilless materials such as peat, vermiculite, and perlite as the substrate and uses plugs with different holes as containers to form seedlings at one time through precise seeding, covering suppression, and watering.

Its characteristics are one hole for seeding when sowing, one hole for one plant for seedling, each seedling has an independent space, water and nutrients do not compete with each other, the seeding age is 10-20 days shorter than that of conventional seedlings, and the seedlings grow faster.

No soil-borne diseases and the root tufts of the seedlings are not easy to disperse, the root system is complete, the planting does not damage the roots, the seedlings are slow, and the survival rate is high. It is suitable for long-distance transportation and is conducive to standardized management.

In addition to this form of nursery seeding machine, we have another form, as shown in the following video:

The two seed sowing machines have the same function and different appearances. Customers can choose according to their needs.

Two types of nursery seedling machine

We have two types of nursery seeding machines, one is a manual nursery seedling machine and the other is an automatic seedling nursery machine. They all have their own characteristics and advantages.

2BXP-5500 seed sowing machine

2BXP-5500 is a manual seed sowing machine. It can meet the planting and seedling needs of vegetable production bases. This machine can greatly reduce labor costs in sowing and seedling production, and improve the quality of seedling production.

This machine is small in size, light in weight, flexible in operation, and simple in structure. It can be put into operation immediately by providing a 220V universal power supply. Pressing holes, taking seeds, and sowing are completed at one time. The largest seeds which can be sowed are as follows: soybeans, peas, corn, pumpkin, etc. The smallest seeds are petunia (tens of thousands of grains per gram), celery, cabbage, etc. The conventional seeds are eggplant, pepper, tomato, lettuce, and other seeds. Because it is a manual machine, manual participation is required in the operation process, and multi-person collaboration is required.

Operation process of the manual seed sowing machine:

For the first step, you need to manually put the cultivation soil into the plug; in the second step, place the plug on the machine, and use your feet to step on the machine to accomplish the aim of pressing the hole and seeding operation at one time; the last step, remove the plug and then put some cultivating soil on the upper part of the plug.

Technical parameter of 2BXP-5500

| Size | mm | 1140*630*840 |

| Turbofan | w | 750 |

| Applied Tray | mm | 540*280 |

| Electric Power | v | 220 |

How does the machine to sow seeds?

YMSCX-750 vegetable seed sowing machine

YMSCX-750 is an automatic vegetable seed sowing machine, which can be operated through a touch screen. The machine includes a soil loading system; central controlling and cavity pressing system; seed sowing system and a mainframe with the transmission system. With a long production line, it can efficiently raise seedlings and can complete 750 trays per hour, so it can reduce manpower input.

Working process of groundnut seeder machine

When using the automatic seedling nursery machine, the seedling tray is set on the conveyor belt, and the seedling tray is transported by the conveyor belt. During the seedling tray transportation, the subsoil covering box wants to sprinkle the seedling on the seedling tray. And then the seeding box sprinkles the seeds on the subsoil, and finally, the topsoil covers the box.

Sprinkling the top map on the seeds realizes the automation and mechanization of seedling raising, and can ensure the consistency of the thickness of the subsoil, planting, and topsoil. And nursery seedling machine can ensure consistent seed growth efficiency; through the setting of the transport vehicle, the seedling tray is transported to make the seedling more convenient.

Technical parameter of YMSCX-750 nursery seedling machine

| Model : | YMSCX-750YMSCX-750 |

| Sowing Efficiency : | 750 trays/hour |

| Sowing Method : | Needle sucking with air-blowing function |

| Electric Power: | Totally 1.5kw (including 0.75kw blower) / 220V 50Hz 1-phase |

| Applied Seed : | Spherical or Non-spherical 0.1-5mm (surface no blur) |

| Sowing Accuracy: | Spherical ≥95%; Non-spherical ≥90% |

| Applied Tray: | Outer size 540*280mm (32 / 50 / 72 / 105 / 128 / 200 / 288 plugs) |

| Size / Weight : | 3350*890*1220mm / 500kg |

| Air Compressor (optional) : | ≥ 0.7MPa (for pneumatic cylinder operation) |

| Others : | KIMPO vacuum blower / 250w Gear … |

How to sow the vegetable seeds into the tray?

Benefits of seedling machine

1. Save seeds. These two nursery seedling nursery machines are accurate in sowing, effectively aligning the holes so that the number of seeds is accurate, and the waste of seeds is reduced.

2. According to different seeds and sowing requirements, the corresponding seeding board and seed suction head can be configured.

3. When sowing seeds, one tray at a time, compared with the seedling raising machine that sows one row at a time, it is extremely efficient.

4. 750 watts imported rotary worm fan with strong suction power.

5. Different seeding boards can be equipped according to the customer‘s needs, and the seeding boards are matched with plug trays.

Factory and delivery

Our factory is strong and has sufficient inventory. Our workers have rich experience and take the quality of the products very seriously. Each product has been checked at various levels and the quality is strictly controlled. Regarding delivery, we use wooden boxes for packaging and delivery. The packaging of each product is extremely careful to ensure that the product can be delivered to the customer intact. If you are interested in our nursery seeding machines, you can leave your contact information, our sales consultant will contact you within 24 hours.

Export seed sowing machine to Zambian

A customer from Zambian has purchased a semi-automatic seed sowing machine from us. The customer is a foreign machinery dealer. In addition to the nursery seeding machine the customer also bought trays from us. Our sales manager Winnie talked to the customer about all questions regarding the nursery tray seeder, such as production capacity, suction needles, type of seeds, voltage, shipping agents, etc. Then the customer said he would come back to our factory and here is a video of the customer visiting the nursery and the factory. Feel free to subscribe to our youtube channel and ask about our nursery seeding machines!

Zambian customer visit our factory and nursery seeding machine