Rice Destoner Machine | Stone Impurities Removing Machine

Rice Destoner Machine | Stone Impurities Removing Machine

Rice destoning machine | Paddy destoner

Features at a Glance

With the double core technology of “specific gravity sorting + air flow suspension”, the rice destoner machine realizes the separation through the density difference between materials and stones (the specific gravity of stones is 2.5-3.0g/cm³, while that of rice is only 1.1-1.3g/cm³).

Combined with an adjustable inclined screen surface and an intelligent wind pressure system, this machine can efficiently process 1 ton of rice per hour. It is mainly used in the primary processing of rice, wheat, and other grains, and is widely used in rice mills, grain depots, and all kinds of grain processing enterprises.

With a compact structure, 2.2kW motor, and ≥95% de-stoning rate, the rice destoner machine is not only easy to operate, but also has a remarkable separating effect, which is the ideal choice to improve the purity and production efficiency of rice.

Advantages of rice destoner machine

- High impurity removal rate: adopting advanced sorting technology, it can completely remove stones, gravel and other impurities to ensure that the rice is clean and free of foreign matter, and improve product quality.

- Stable operation: the whole machine has a compact structure, and the power system runs smoothly, which effectively reduces vibration and noise and improves working reliability.

- Strong processing capacity: it can process about 1 ton of rice per hour, which is suitable for small and medium-sized grain processing plants to meet the demand for efficient continuous operation.

- Easy operation and energy saving: easy to use, simple operation process, reduce manual intervention, save labor and energy costs.

Rice stone remover technical parameters

| Model | SQ50 |

| Productivity | 1t/h |

| Power | 2.2kw motor |

| Dimension | 900*610*320mm |

| N.Weight | 86kg |

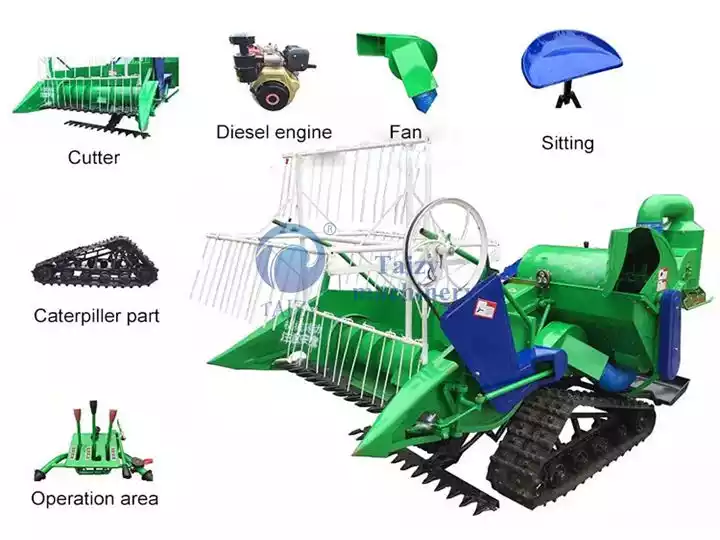

Main structure of rice destoner machine

The wheat stone removing machine mainly consists of a big stone outlet, an impurity outlet, a clean rice outlet, a small stone outlet, and a rice feeding hopper.

Rice de-stoning machine working principle

- The operator drops the rice or wheat into a feeding hopper when the rice destoner machine in Nigeria begins to work.

- 2.2kw motor powers the machine, so the electric screen vibrates constantly.

- The stone is moving upward, while rice or wheat runs in the opposite direction.

- After several minutes, clean rice, small stones, big stones, and other impurities go out from different outlets.

Preoccupation of rice destoner machine

- Before starting, the screen surface, fan and all fasteners should be checked, and the pulley should be manually rotated to confirm that there is no abnormality before starting the machine.

- The inclination angle of screen surface should be kept between 10°-13°, too big or too small will affect the effect of de-stoning, and can be adjusted according to the content of stones.

- There should be a proper amount of paddy in the feeding port to avoid direct impact of paddy on the screen surface to affect the suspension state and the rate of de-stoning.

- The air volume should be adjusted according to the movement of the paddy on the sieve surface, and the vibration is too strong, which means that the air volume is too large, and not floating, which means that the air volume is too small.

- Wind door, air ducts, sieve holes should be kept free, such as clogging can be cleaned with a wire brush.

- Operation process should always observe whether there are still stones in the finished paddy, and adjust according to the situation.

- The equipment should be regularly overhauled, cleaned bearings and filled with lubricating oil, and after overhauling, it needs to run empty to confirm that there is no error.

Cost-effective stone removing rice mill

In addition to the separate de-stoning machine, we also provide rice de-stoning and polishing machine. This equipment can complete the removal of impurities, de-stoning and fine milling of rice in one go, which greatly improves the processing efficiency and saves labor and site costs. Welcome to watch the video below.

Successful case of rice destoner machine

Our customer from South Africa placed 500 sets of paddy rice destoning machines from us this year. We have cooperated with him many times and he works for local government. Therefore, we emphasize great importance to this wheat destoner to make him satisfied.

We finished all the machines within one month and packed them carefully in case of any accidents during delivery. Until now, he has received machines and given us good feedback.

FAQ

What is the raw material of destoner machine?

The raw material is rice and wheat.

What is the cleaning rate?

The cleaning rate is 98%, which means the final kernels are very clean.

Why does the final rice contain little stone?

The wind volume is small and it should be adjusted in time.

Contact us at any time

If you are interested in our stone removing machine or have any related questions, please feel free to contact us for more information! If you are interested in rice processing, you can refer to our: Rice Milling Plant Machine丨Automatic Rice Mill Production Line.

We sincerely invite you to visit our factory in person to witness the quality of our products and processes and experience the actual working performance of our products. We look forward to working with you!