Furrow Plow | Reversible Furrow Plough | Hydraulic Flip Plow

Furrow Plow | Reversible Furrow Plough | Hydraulic Flip Plow

Plough for tractor | Furrow plowing machine

The furrow plow is a fully-suspended agricultural implement used to cultivate the soil. This promotes the decomposition of soil organic matter, improves soil fertility and water storage capacity, improves soil structure, eliminates pests and diseases, and achieves improved water, fertilizer, gas, and heat conditions in the soil.

This tractor furrow plow can improve the soil moisture retention capacity, and eliminate some weeds.

And reduce diseases and insect pests, level the ground, and improve the standards of agricultural mechanization operations. It has the characteristics of a simple structure, a wide range of farming adaptability, good operation quality, smooth surface, good performance of broken soil, and small moisture ditches.

Farming tractor furrow plow structure

The furrow plow consists of the main plow body, plow frame, traction part, plow wheel, and other parts.

To ensure the quality of cultivated land, accessories such as round colters, small front plows, and small colters can be installed in front of the main furrow plow body according to the farming requirements and soil conditions.

In addition, you can also choose a furrow plow with different numbers of colters according to the different soil conditions.

Types of furrow plow

- According to the form of coupling with the tractor, it is divided into traction, suspension, and semi-suspension.

- According to the power used, it is divided into animal power plow, and mechanical plow (tractor plow).

- According to the different structures, it divides into a two-way plow, amplitude modulation plow, etc.

- According to the number of operating furrow plow bodies, it is divided into a double-shaft plow, three-shaft plow, four-shaft plow, and five-shaft plow.

Agricultural furrow plow machine advantages

- If the plow in cold and temperate soils, the depth does not exceed 20 cm, it can loosen the soil and can make the crop straw, fertilizer, and limestone in the soil interact with oxygen.

- Reduce the loss of nitrogen fertilizer caused by volatilization, make the organic matter in the soil turn into humus faster, and make the soil more fertile.

- The plow will eliminate wheel tracks and ruts left by the harvesting equipment. It is also possible to control the growth of perennial weeds before the following spring. Because the upper layer of soil is less, it will accelerate soil warming and water evaporation in spring. So it is helpful to use a lighter planter to sow.

- Plowing can reduce many natural enemies of crops (such as slugs, crane mosquitoes, fruit flies, borers, etc.) and increase the number of soil-feeding earthworms.

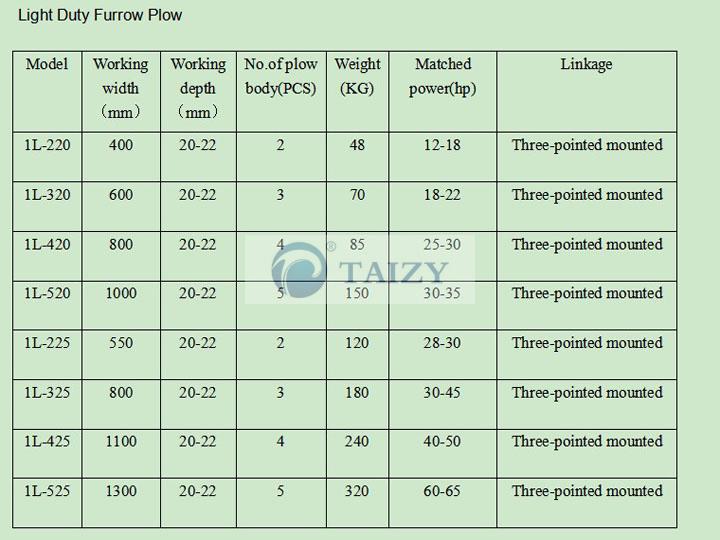

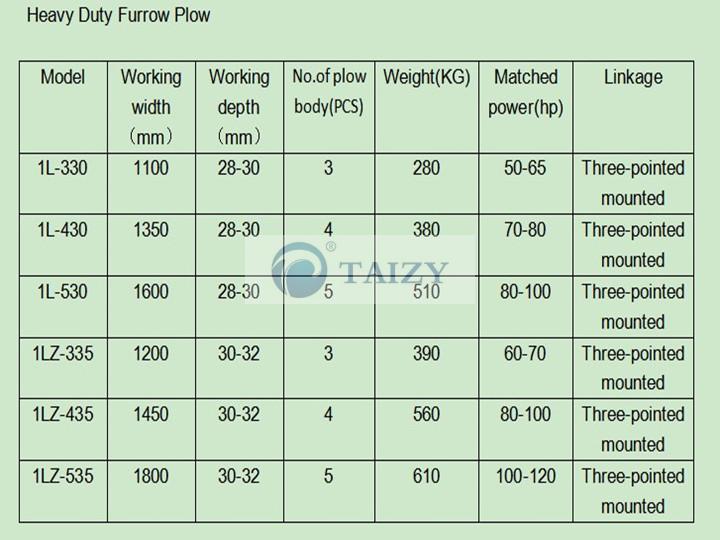

Parameters of furrow plows

Light-duty furrow plow

Heavy-duty furrow plow

Price of a furrow plow

Due to different models, the specific price will vary. You can consult our sales staff, they will recommend the machine only suitable for you according to your needs. They will send you a quotation for the relevant machine at the same time.

Introduction of hydraulic flip plow

Hydraulic flip plow, also known as reversible furrow plow. When using the hydraulic flip plow, you should conjunction it with the tractor. This series of flip plows is suitable for soil, sandy soil areas, and dry farming.

Structure of the hydraulic flip plow

- Including suspension frame, turning cylinder, non-return mechanism, ground wheel mechanism, plow frame, and plow body.

- The plow frame equips a ground wheel mechanism.

- Which characterizes that the cylinder body of the turning oil cylinder connects with an oil cylinder seat connected to the plow frame.

- The rear end of the central sleeve outside the central shaft connects to the piston rod.

- The oil cylinder seat and the plow frame connect to drive the central shaft to rotate in the central shaft sleeve.

Advantages of hydraulic flip plow

- The structure of the amplitude-modulated flip bidirectional plow is reasonable.

- Equips with various types of components.

- Adapt to different farming conditions and unit-matching requirements.

- It equips safety protection devices, using high-quality materials, hydraulic components, and advanced manufacturing technology.

Difference between split plow and hydraulic flip plow

- The split plow has good turning over and covering performance, which is unmatched by other arable land machines.

- The split plow is an arable land machine widely used in the long history of agricultural production in the world.

- Most split plows can only turn the ridge in one direction, and it will form a closed ridge after turning the ridge.

- Through the turning mechanism, the two groups of plow bodies work alternately in the reciprocating stroke, forming a shuttle-shaped farming operation.

Correct use and adjustment of hydraulic flip plow

Preparation before ploughing

- The first is to check the integrity of the machine tool. Whether there is any damage or missing parts, and whether the bolts are loose. Ensure that the equipment is intact. And fasten the bolts.

- The second is to adjust the configuration of the first part of the flip plow. When a wheeled tractor is plowing, generally one wheel has to go in the furrow. The inner side of the tire that walks in the furrow and the wall of the trench generally maintain a gap of 1-2cm. If not, when the hydraulic flip plow shuttles back and forth, it will leave furrows or ridges between each working width.

- The third is to check and adjust the wheelbase. Check the distance H between the inner side of the tractor’s rear wheel and the distance h from the side plate of the first plow of the flip plow to the center of the shaft. It is required to meet H/2=h+b, and b is the single plow width. When this condition cannot be met, adjust the flip plow. If you cannot adjust the flip plow, adjust the tractor track to meet the requirements.

- The fourth is to check the tire pressure. When plowing, the tire pressure should be 80-110KPa. The specific instructions shall prevail.

- Fifth, check whether the hydraulic oil of the tractor is enough and whether the hydraulic quick coupling is intact. When connecting with the hydraulic oil pipe of the flip plow, connect according to the oil pipe mark on the flip plow.

Connection of the tractor and plow

After the inspection, we are going to hook up the hydraulic flip plow. The coupling of the tractor and the hydraulic flip plow is a three-point suspension. Before hooking up, we must first adjust the left and right pull-down rods to ensure the level of the left and right pull-down rods.

- The specific adjustment method is as follows: park the tractor on a flat road, use the hydraulic lifting handle to drop the pull-down rod, and check whether the center of the ball joints connected to the left and right pull-down rods is consistent with the ground height.

- After the left and right, pull-down rods are leveled, the hydraulic flip plow will be hooked up.

- Connect the ball heads of the left and right pull-down rods to the left and right lower suspension points of the plow respectively, and lock them with pins to prevent them from falling off.

- After the pull-down rod is connected, connect the upper pull rod of the tractor, connect the upper pull rod and the upper suspension point of the hydraulic flip plow with a pin, and lock it with a pin to prevent it from falling off.

Adjustment of the plow frame

- When the tractor is plowing, we adjust the horizontal level of the plow frame of the hydraulic flip plow to ensure that the plow post is vertical to the ground during plowing.

- The tractor has a certain inclination angle, which will cause the plow frame to be lateral, not horizontal, that is, the plow post is not perpendicular to the ground.

- By adjusting the length of the two limit screws on the left and right, the plow column can be perpendicular to the ground after the plow enters the soil.

- When adjusting the vertical level of the plow frame, it is mainly to adjust the length of the upper rod.

- When the plow frame is low in the front and high in the back, the first plowshare of the flip plow will be too deep, and the rear section will be too shallow.

- At this time, it can be solved by lengthening the upper tie rod; and if the plow frame is high in the front and low in the rear, it will cause the first plowing depth to be too shallow and the rear part too deep, and it is difficult to plow into the soil.

Adjustment of working depth and working width

- For the adjustment of working depth, hydraulic flip plows generally have limited-depth wheels.

- And you can adjust the working depth by adjusting the depth limit wheel screw.

- The way to adjust the working width is generally to adjust the length of the screw.

Angle of the reversible furrow plows into the soil

- Regarding the adjustment of the angle of the turning plow into the soil, to make the turning plow perform well in the soil under different soil conditions, many turning plows have the function of adjusting the entering angle.

- After adjusting the angle of soil entry, tighten the fixing bolts and position adjustment bolts.

Flip operation of reversible furrow plow

- The operation methods of the two hydraulic flip ploughs are different when they are flipped.

- As for those without an automatic reversing valve on the cylinder.

- And then manipulate the reversing handle to turn it over.

- Once the turning plow crosses the centerline position, immediately operate the control handle in the opposite direction.

- For the oil cylinder with an automatic reversing valve, you can complete the whole process of turning by turning the control handle in one direction at the time of turning, without needing to reverse the control handle.

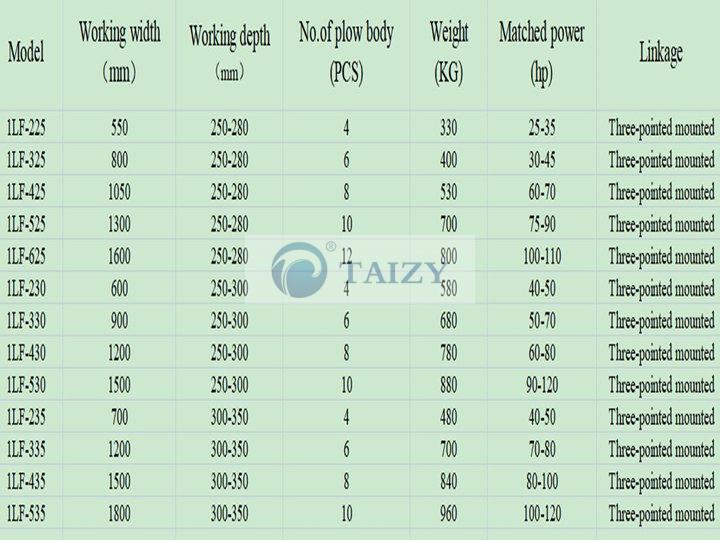

Parameters of reversible furrow plow

Maintenance of reversible furrow plow

- Regularly remove the dirt and weeds that stick to each plough’s body.

- Every time you plow a ridge to the ground, pick up the plow during the journey to avoid plowing on the spot.

- After farming, check all parts for damage or loss in time. Once you find a problem, repair and replace it immediately.

- Prohibition of oil leakage or oil leakage in the hydraulic system

- Inject lubricating oil once every 200 acres of land wheelwork. And inject once every shift in other oil injection points.

- Replace the plowshare in time after it warns out. And replace and repair other parts if they warn out.

We warmly invite all our colleagues in the agricultural sector, as well as large farmers and anyone interested in modern agricultural technology, to come and see this innovative furrowing machine in action. Feel free to contact us for more information and machine quotes.