Round Silage Straw Harvester And Baler, Picking And Bundling Machine

Round Silage Straw Harvester And Baler, Picking And Bundling Machine

Straw picking and baling machine | Crop harvesting baler

Features at a Glance

The round straw harvester and baler machine combines multiple functions into one unit, capable of shredding, collecting, and baling field straw in a single pass, significantly reducing labor and transportation costs.

Its compact and streamlined design ensures easy operation and high efficiency, making it suitable for farms of varying sizes and complex terrain. Whether processing corn stalks, wheat straw, alfalfa, cotton stalks, or other crop residues, this equipment delivers rapid and efficient harvesting and baling. It provides a reliable supply of raw materials for farmers, livestock enterprises, and straw-fired power plants.

Round straw harvester and baler machine applicable scope

The silage straw shredder, picker, and baler offers broad applicability and operates efficiently across diverse environments:

- Crop straws: corn stalks, wheat straw, rice straw, cotton stalks, sheepgrass, reeds, etc.

- Forage crops: alfalfa, ryegrass, oat grass, and other feed crops.

- Suitable scenarios: farms, pastures, silage processing sites, livestock farms, straw recycling bases, and fuel supply for straw-fired power plants.

- Operating conditions: processes both upright and lodged straw. Capable of pre-harvest field operations and post-harvest residue recovery.

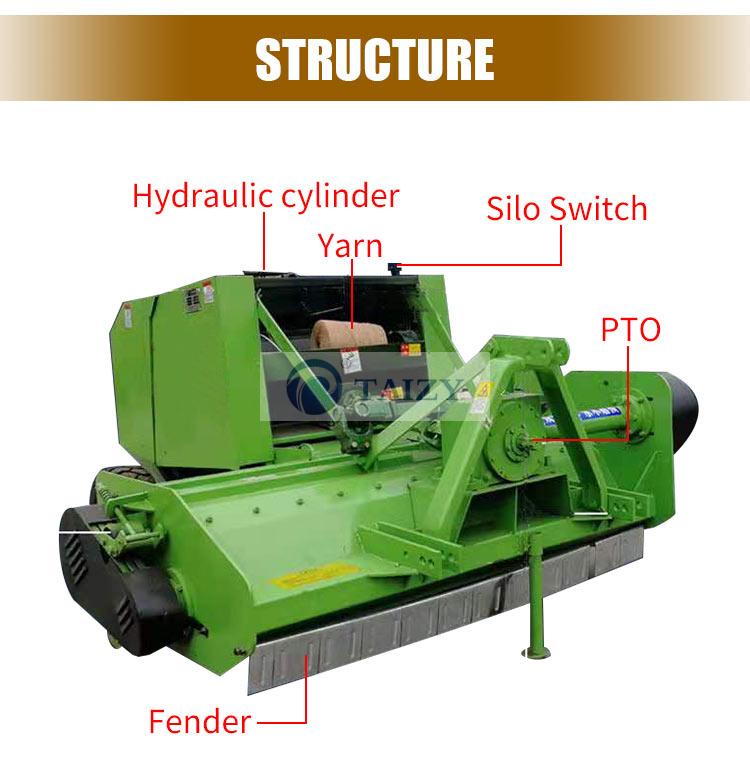

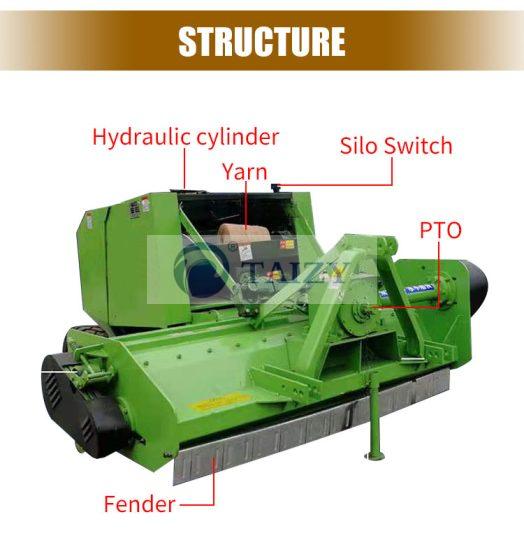

Structure of the forage crushing pick up baler

This round straw harvester and baler machine includes a PTO, crushing mechanism, picker, feeding mechanism, bundling mechanism, and other parts.

- PTO: connect to the tractor through a splined shaft (8 keys). First, start the tractor. And then transmit the power to the machine through the spline shaft.

- Crushing mechanism: breaks up the straw first.

- Picker: picks up and lifts the crushed straw into the feeding platform.

- Feeding mechanism: feeds the straw into the baling mechanism.

- Bundling mechanism: the piston and baling chamber compress and form the straw.

How does the silage cutting, picking and bounding machine work?

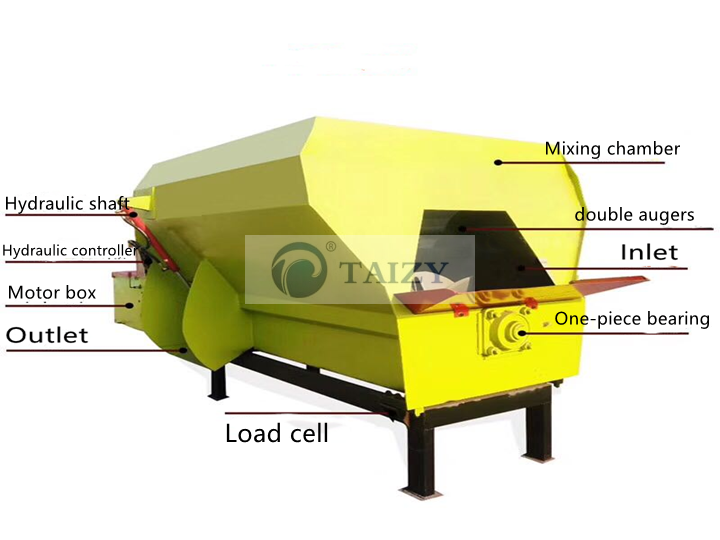

Firstly the round straw harvester and baler machine kneads and crushes the straw first. After that, the material is thrown into the auger under the inertia of the machine. The auger pushes the material to the feeding port.

Then the feeding fork sends the material into the compression chamber of the round straw harvester and baler machine.

Finally, the warehouse is hydraulically opened and bundled. The bundled forage is convenient for transportation, storage, and further processing.

The power output shaft of the tractor inputs the power to the input shaft of the round straw harvester and baler machine through a Cardan shaft.

After that, the sprocket and chain drive the rolling and pressing roller mechanism and the straw picking mechanism respectively.

Then we use the tractor hydraulic output interface to control the expansion and contraction of the cylinder piston to realize the bale unwinding operation.

Parameter of automatic corn stalk harvester and baler machine

| Model | Recovery width(mm) | Work efficiency(acre/day) | Power(kw/ml) |

| 9YY-0.5 | 1650 | 30-50 | >50 |

| 9YY-0.7 | 1800 | 50-90 | >50 |

Round stalk crushing, picking and strapping machine characteristic

- All-in-one functionality: simultaneously shreds, collects, and bales, saving labor and streamlining processes.

- High-efficiency operation: processes 0.82–1.3 acres of crop residue per pass, significantly boosting productivity.

- Adjustable baling: flexibly customize bale length and dimensions to meet transportation and storage requirements.

- Operational flexibility: compact design suits small plots, easily operated by a single person.

- High adaptability: compatible with small to medium-sized four-wheel tractors, delivering stable power and broad applicability.

- Safe and reliable: equipped with a safety clutch and shear bolt mechanism that automatically disconnects power during overload to prevent damage.

- Excellent bale quality: Produces dense yet breathable bales ideal for storage, transport, and subsequent utilization.

- Easy maintenance: simple construction with low failure rate, minimizing routine maintenance and repair costs.

Why choose our straw cutting, picking and strapping machine?

Whether for straw silage feed, livestock forage reserves, or straw fuel supply, our equipment helps you save time and labor costs while addressing challenges related to straw transportation and storage.

With its stable performance and broad applicability, it has become the ideal choice for farmers and large-scale livestock enterprises. We also have square bale straw pickup balers available. Contact us today for more machine details and customized solution quotes!