Peanut Picker Machine丨High Efficiency Groundnut Picking Machine

Peanut Picker Machine丨High Efficiency Groundnut Picking Machine

Groundnut Picker | Peanut Picking Machine

Features at a Glance

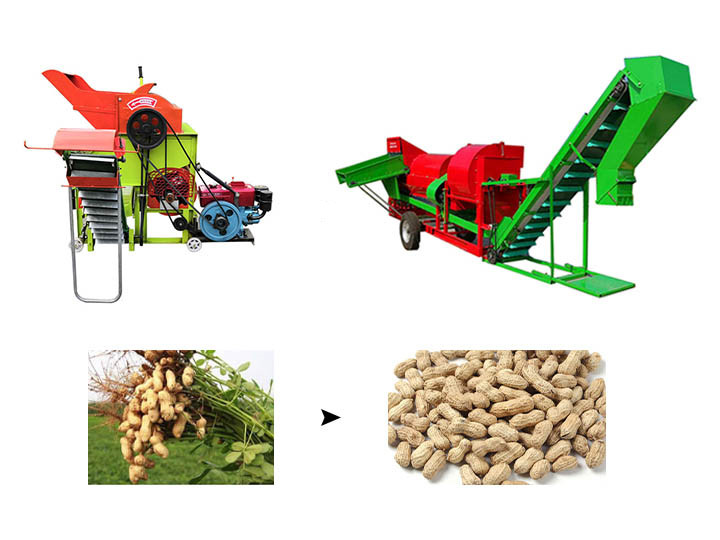

The peanut picker machine is a highly efficient agricultural device designed to separate peanut pods from seedlings, making it an indispensable piece of machinery in the post-harvest processing stage of peanut production.

The machine is easy to operate, ensures clean pod separation, and operates at high efficiency, making it an ideal choice for modern peanut farmers and processing companies looking to enhance efficiency and reduce labor costs.

We offer two different models with varying production capacities: the compact 5HZ-600 and the large 5HZ-1800. These models cater to the needs of users with different planting scales. The large model is further divided into square fan, round fan, and fruit box types, offering diverse structures and strong adaptability.

The importance of peanut picker machine

- Replacing labor-intensive manual work: traditional manual peanut harvesting is time-consuming, labor-intensive, and inefficient, especially in large-scale planting scenarios. The Taizy peanut harvester significantly reduces labor intensity.

- Enhancing picking efficiency and quality: through continuous optimization and upgrades, the equipment can quickly separate peanuts from seedlings, resulting in low fruit damage rates, clean fruit output, and low impurity levels.

- Promoting mechanization in the peanut industry: this equipment, when used in conjunction with our company’s peanut planters, peanut harvesters, peanut shellers, and peanut oil press machines, forms a complete peanut processing chain, helping farmers achieve integrated and efficient peanut production.

Groundnut picking machine operation video

Type one: small size groundnut picking machine

The 5HZ-600 peanut picker machine is ideal for individual farmers. This machine can process approximately 800-1000 kilograms of peanuts per hour and operates efficiently with a 7.5kW motor or a 10 horsepower diesel engine.

The machine achieves a shelling rate of up to 99%, with breakage and impurity rates both below 1%, ensuring high-quality shelling results and clean, tidy finished products.

The rear is equipped with a lifting device that effectively collects peanuts and filters out impurities again, enhancing overall cleanliness, making it an ideal choice for small-scale peanut growers.

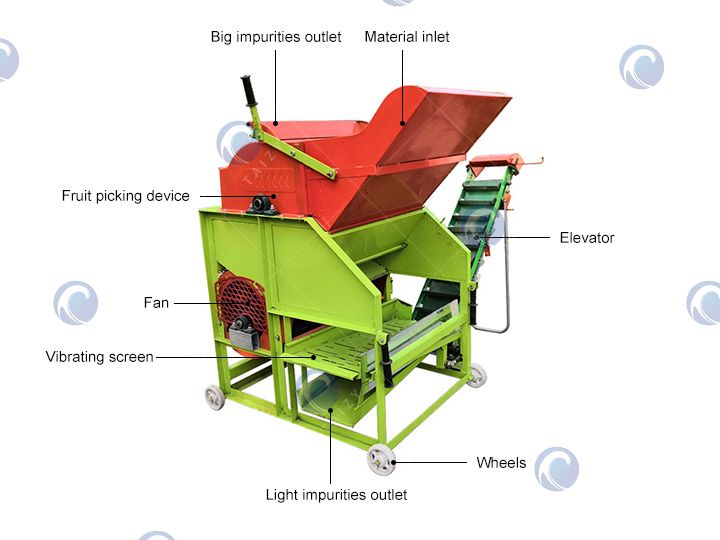

Structure of peanut fruit picking machine

This model of peanut fruit picking machine is mainly composed of a material inlet, impurities outlets, fans, a fruit picking device, a vibrating screen, an elevator, wheels, and power(motor or diesel engine). The volume and simple structure of this model machine are suitable for home use in our daily lives.

Small size groundnut picking machine advantages

- Sturdy structure: the lifting device has a symmetrical structure, operates stably without deviation, and is equipped with a protective cover to ensure cleaner peanuts.

- Double-layer screen: an additional soil-removal screen enables timely soil removal, resulting in cleaner screening.

- Enhanced airflow: a six-blade design generates strong airflow, ensuring thorough separation of peanuts from straw.

- Excellent cleaning performance: the core cleaning system ensures peanuts are cleaner with fewer impurities after harvesting.

- Easy maintenance: high-quality steel rollers are used, which are removable for convenient maintenance and replacement.

Small peanut picking machine technical parameters

| Model | 5HZ-600 |

| Size | 1960*1500*1370mm |

| Weight | 150Kg |

| Power | 7.5kw motor,10HP diesel engine |

| Capacity | 800-1000kg/h |

| Picking rate | >99% |

| Breaking rate | <1% |

| Impurity rate | <1% |

| 40HQ | 45 sets |

Working procedures of peanut seedlings remover

First, check if there is a problem with the machine. For example, loose screws, foreign objects inside the machine, etc.

Read the manual carefully. Then turn on the machine and put the peanuts with seedlings in the machine through the feeding port.

Then the dry peanut picker machine’s fruit picking device will work. And at the same time, the fans blow the impurities out through the impurity outlet.

Next, the groundnut picking machine’s vibrating screen will shake off the soil and sand on the peanut shells.

Finally, the processed peanut enters the bag through the elevator.

Type two: big size peanut picker machine

The TZY-1800 peanut picker machine is a highly efficient machine designed for large-scale peanut cultivation, featuring outstanding automation capabilities.

A powerful fan effectively separates peanut plants and weeds, enabling automatic separation of peanut pods from plant debris. Additionally, the machine is equipped with an automatic bagging system, significantly enhancing operational efficiency.

This machine is suitable for both dry and wet peanuts, offering fast harvesting speed and excellent cleaning performance. The entire machine is constructed with widened drums and thickened steel, making it suitable for continuous operation. It supports tractor-towed mobility, offering flexible and convenient operation, and is highly suitable for large-scale field operations.

What are the features of this big-size peanut picker?

- The widened inlet can convey peanut seedlings automatically.

- The optimized fan with strong wind can blow out the impurities.

- The wheels can save manpower.

- Wide tires enable it to bear good stability.

- It is fixed with u-shaped screws, which are more flexible and convenient.

- Stable transmission performance.

- Automatic loading and bagging are very convenient, and the peanut picker machine itself can be disassembled flexibly.

- The two support rods at the inlet can make the machine more stable.

- The widening drum can increase output.

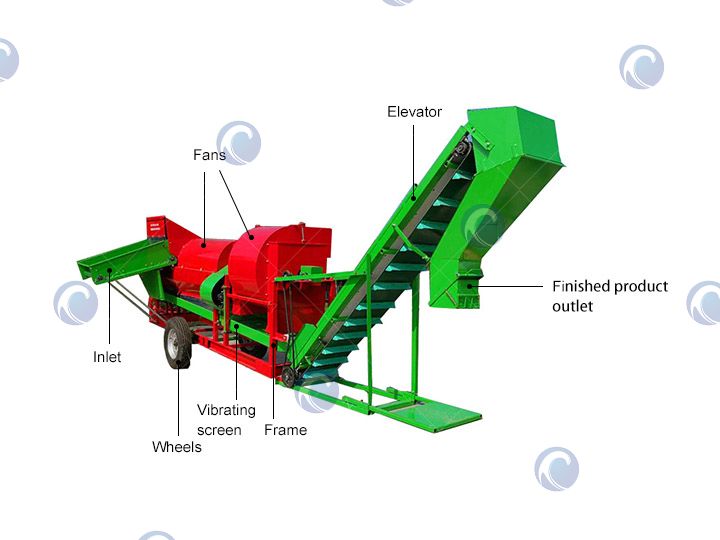

Components of a peanut picking machine

This peanut picking machine includes a frame, PTO, inlet, seedlings removing device, fans, vibrating screen, two impurities outlets, wheels, elevator with hook, etc.

How to properly use the groundnut picker machine?

- Before the operation, turn the pulley by hand to see if it works normally, and check whether the fruit picking is complete.

- When placing peanut seedlings into the machine, the side with the peanut fruit must be put into the inlet first. And the feeding speed shall be uniform.

- The fruit picking machine should not be overloaded, Inspection, adjustment, and maintenance are the necessary things when all is finished.

- When the drum of the fruit picker is blocked, check the feeding amount. The following factors can trigger this situation such as the dryness of the peanut seedlings, the tightness of the motor triangle belt, and the power supply voltage.

- If the picked peanuts are not clean, adjust the gap between the drum and the bottom of the screen.

- When the peanut fruit contains a lot of impurities, at the same time, the small peanuts are sucked out. You should adjust the draught fan outlet.

Technical parameters of big size peanut picker

| Model | 5HZ-1800 |

| Power | 25-37kw |

| Rotation speed of the roller | 550r/min |

| Loss rate | ≤1% |

| Broken rate | ≤3% |

| Impurity rate | ≤2% |

| Capacity | 1100kg/h(wet peanut) |

| Inlet dimension | 1100*700mm |

| Height from inlet to the ground | 1050mm |

| Weight | 720kg |

| Model of separation and cleaning | Vibrating screen and draught fan |

| Dimensions of the screen | 3340*640mm |

| Dimension of machine | 5800*2100*1900mm |

| Diameter of the roller | 600mm |

| Length of the roller | 1800mm |

| Capacity unit power | ≥30kg/kWh |

Peanut picker customer feedback

Peanut picker machine feedback from Italian customers

Italian customers bought peanut harvester and peanut picker machines from us, and the customer gave us satisfactory feedback after receiving the machine. The harvested peanuts are arranged in the field in an orderly manner. Then they picked after finishing the whole harvest.

It needs manual feeding to put the harvested peanuts into the hopper, then the peanuts can be picked automatically. We can see that there is a conveyor belt in the hopper, which makes it easier for peanuts to enter the machine.

The removed peanut leaves or peanut stalks are blown out through the blower. The peanuts are conveyed through the conveyor belt. The clean peanuts are conveyed to the collection bag.

Peanut picker machine feedback from Sri Lankan customers

This is our peanut picker working feedback video from Sri Lankan customers. He bought a small size groundnut picking machine. From the video, we can see that one person can operate this machine, and the picking efficiency is very high, which is dozens of times that of manual work.

The peanut removing machine is started by a diesel engine, and the output is 800-1000kg/h. The picking rate is 99%. The peanuts after picking are directly transferred into the collection bag by the conveyor belt. It is very convenient.

If you are interested in the peanut picker machine then feel free to contact us for more pictures and videos and a quote for the machine. We are looking forward to cooperating with you.