Automatic Corn Sheller | Maize Shelling Machine

Automatic Corn Sheller | Maize Shelling Machine

Maize Thresher | Corn Threshing Machine

Features at a Glance

The automatic corn shelling machines are used to quickly separate corn kernels from the cob. Our hot-selling TY-80A, TY-80B, TY-80C, and TY-80D models are all equipped with a high capacity of 4-6 tons/hour.

They are widely used in scenarios such as farms, cooperatives, and agricultural planting areas, and are especially suitable for centralized use in rural areas where agriculture is the main focus.

One machine can serve an entire village, greatly improving threshing efficiency and saving labor costs, making it an ideal choice for farmers to achieve efficient grain processing.

Advantages of hot sale corn sheller

- High degermination rate: the degermination rate is up to 99.5% or more, almost no broken and residue.

- Extremely low impurity: after the wind selection and vibration screening system, the corn seed is clean and free of impurity, the impurity rate is less than 1%.

- Strong production capacity: the corn shelling capacity can reach 4-6 tons per hour, far exceeding similar products in the market.

- Automatic feeding: equipped with an automatic feeding hopper, effectively improving feeding speed and saving labor.

- Advanced structure: built-in threshing drum, fan, elevator, chaff sucker and screening system are integrated design, realizing automatic cleaning and selection.

- Multi-choice of power: support equipped with 15 hp diesel engine or 7.5 kW motor, flexible to adapt to different power environment.

- Suitable for rural collective use: high efficiency and durability, one machine shared by many households, suitable for agricultural cooperatives and rural centralized operation.

Working principle of corn thresher

- Automatic feeding: put the whole cob of corn into the automatic feeding conveyor belt, and the equipment automatically feeds it into the threshing chamber.

- Threshing and separating: the roller in the threshing chamber operates at high speed, rolling and rubbing the corn, separating the kernels from the cobs.

- Preliminary screening of kernels: the threshed corn kernels together with a small amount of impurities fall into the agitator and are sent to the vibrating screen by the elevator.

- Separation of impurities: smaller impurities will fall through the aperture of the screen, and larger impurities will move with the corn to the discharge port.

- Secondary purification: high-efficiency vacuum fan automatically sucks away the fine impurities such as corn husk to further enhance the net seed rate.

- Kernel collection: the cleanly screened corn seeds enter the collection bag or discharging device from the discharging port on the screen.

- Corn kernel discharge: the corn kernels after threshing are automatically discharged from the straw outlet, which is convenient for unified treatment or recycling.

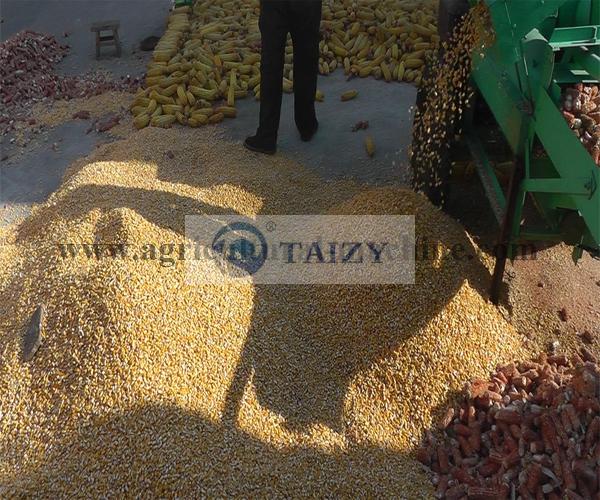

Three ways to collect the corn seeds

- Ground spreading: corn seeds can be discharged directly into the ground, suitable for subsequent drying and drying treatment.

- Collection bag storage: connected to a cloth bag through the interface, the clean corn seeds are directly bagged and stored, which is easy for transportation and storage.

- Cart loading: seeds can also be discharged into a cart, suitable for centralized transportation or on-site sale to buyers and retailers.

Maize sheller machine technical parameters

| Model | TY-80A | TY-80B | TY-80C | TY-80D |

| Power | 15HP diesel engine or 7.5 KW motor | 15HP diesel engine or 7.5 KW motor | 15HP diesel engine or 7.5 KW motor | 15HP diesel engine or 7.5 KW motor |

| Capacity | 4t/h (Corn seeds) | 5t/h (Corn seeds) | 5t/h (Corn seeds) | 6t/h (Corn seeds) |

| Threshing rate | ≥99.5% | ≥99.5% | ≥99.5% | ≥99.5% |

| Loss rate | ≤2.0% | ≤2.0% | ≤2.0% | ≤2.0% |

| Breakage rate | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% |

| Impurity rate | ≤1.0% | ≤1.0% | ≤1.0% | ≤1.0% |

| Weight | 200kg | 230kg | 320kg | 350kg |

| Size | 2360*1360*1480 mm | 2360*1360*2000 mm | 3860*1360*1480 mm | 3860*1360*2480 mm |

TY-80A TY-80B

TY-80C TY-80D

Successful case of corn shelling machine

Last month, we sold 20 sets of maize thresher machines to Congo, and the following are the delivery pictures.

We also have a small capacity corn sheller machine(Related product: Corn Thresher Machine | Corn Sheller | Maize Peeler and Thresher). You can ask us to know more.

FAQ

What is the difference between the 4 types of corn shelling machines for sale?

Automatical feeding inlet and long lifter can improve the working efficiency, so 4 types of corn shelling machines bear different capacities.

What are their capacities?

4-6t/h.

Why are corn cobs too fragile?

Corn cobs may be rotten or the discharge hole of it is rather slow.

Why are there so many impurities?

Removing one or two discharging parts can improve the threshing rate.

Can the slope of the vibrating screen be adjustable?

Yes, you can adjust the height of two supporting frames.

Can the machine peel and thresh corn?

This machine is a large-volume corn thresher, we have a separate corn-peeling machine.

Contact us at any time

We thank you for your attention and for reading our maize corn shelling machine. If you have any further questions or need to get more detailed information, our professional team is always at your service. You are welcome to contact us at any time, and we will be happy to answer your concerns.