Rice And Wheat Grain Threshing Machine Multi Crops Thresher For Sale

Rice And Wheat Grain Threshing Machine Multi Crops Thresher For Sale

Rice and Wheat Grain Threshing Machine is a specialized agricultural machine widely used in the threshing process of grains such as rice and wheat. The machine efficiently separates the harvested grain particles from the husk layer through the built-in cutting and threshing mechanism to obtain clean grains.

This machine has high production efficiency, clean threshing, no breakage, and low impurity content. This machine can match three kinds of power: diesel engine, gasoline engine, and electric motor, you can choose according to your needs.

Wide Applications Of Grain Threshing Machine

The rice and wheat thresher machine is used to threshing various crops—wheat, rice, soybeans, rapeseed, millet, sorghum, quinoa, etc. The adjustability and adaptability of the grain threshing machine make it suitable for different types and sizes of farms.

Thresher Machine Finished Product Display

The finished product obtained from this grain threshing machine is very clean and maintains the integrity of the grain with uniform grains, ensuring the quality of the finished product and improving the harvest rate of the grain.

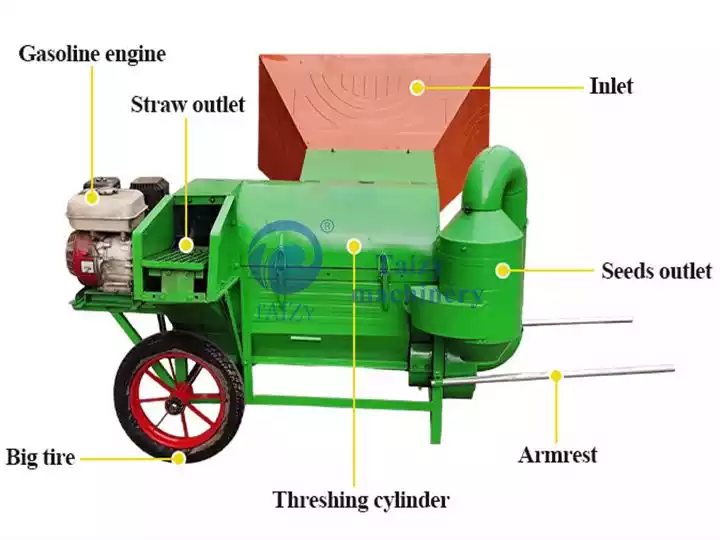

Wheat And Rice Threshing Machine Main Structure

The structure of this grain threshing machine is very simple and mainly consists of a feeding hopper, outlet, threshing drum, sieve, blower, engine, etc. The bearings are well-designed and easy to move with wheels. In addition, different sizes of sieves are available for different grains.

How The Wheat Rice Thresher Works

The rice and wheat thresher works in two main stages: cutting and threshing.

- Cutting stage: In this stage, the grain threshing machine cuts the stems of the harvested grain (such as rice or wheat). This cutting process helps to separate the entire plant from the roots in preparation for subsequent threshing.

- Threshing stage: The cut plant passes through the threshing section of the threshing machine. In this section, the machine usually consists of a roller or cylinder with serrated or grooved teeth, mated with a paddle or scraper. As the plant passes through these sections, the grain is subjected to mechanical forces that separate it from the stem and husk. In this way, the machine is able to efficiently separate the edible part of the grain (kernels) from the non-edible part (hulls and stems).

Benefits Of Paddy Rice Threshing Machine

- Simple structure, convenient operation, and easy maintenance.

- The threshing rate is as high as 98%, and the final kernels are very clean.

- High applicability, can handle rice, wheat, sorghum, millet, beans, and other crops.

- with adjustable parameters, farmers can adjust according to factors such as grain type and humidity to get the best threshing results.

The traditional manual threshing method was inefficient and prone to grain loss. With the introduction of the multifunctional thresher, not only can more harvest be accomplished in the same amount of time, but food waste is also reduced.

Multi-purpose grain threshing machine is widely welcomed in many countries, especially in Asia, Africa, and Latin America where agriculture is dominant, and has been shipped to Kenya, Nigeria, India, Indonesia, the United States, Russia, Bangladesh, Australia, and other countries.

Paddy Thresher Machine Parameters

- Model: 5TYC1-90

- Power:170F gasoline engine, Dia 70cm belt wheel, rated speed 3600 rpm

- Capacity: 600-800kg/h

- Threshing cylinder: Dia 360*Length 900mm

- Sieve size: 870*610mm

- Weight: 90kg without engine

- Overall size:1640*1640*1280mm

- 24pcs/20GP, 66pcs/40HQ

This is a hot model that meets the public for crop processing, we also have other models to choose from, please feel free to contact us for more models of grain threshing machines and related information.