Automatic Groundnut Sheller Machine For Sale

Automatic Groundnut Sheller Machine For Sale

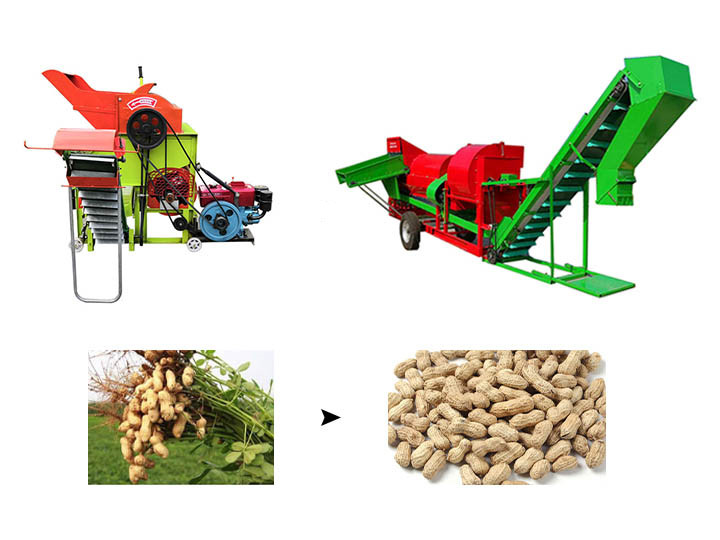

Peanut Shelling Machine | Groundnut Thresher

Features at a Glance

The small groundnut sheller machine is widely used in farms and processing plants. The machine combines drum friction and air separation to shell peanuts, achieving a shelling rate of over 95% and effectively ensuring a kernel integrity rate of approximately 90%.

Compared to traditional manual shelling, efficiency is improved by several times, significantly reducing labor costs while enhancing the cleanliness and market value of peanut kernels. Whether for small-scale farmers or medium-sized processing enterprises, this equipment is an ideal choice for boosting productivity and competitiveness.

Finished products display

- High peanut kernel integrity: after shelling, the peanut kernels have a smooth surface and low breakage rate.

- Complete shell-kernel separation: the shells and kernels can be efficiently separated, reducing the need for secondary sorting.

- High cleanliness: the peanut kernels contain few impurities, making them suitable for direct processing in the next step.

- Stable output: the machine can operate continuously, producing a uniform output to meet bulk production requirements.

Features of peanut shelling machine

- High-efficiency shelling: fast shelling speed, with efficiency 3-5 times higher than manual labor.

- High adaptability: can process peanuts of different specifications and varieties.

- Adjustable parameters: some models support gap and airflow adjustment to ensure optimal shelling results.

- Durable and reliable: made with high-quality steel and wear-resistant components, suitable for long-term high-intensity operations.

- High capacity: small models can process 300-800 kilograms per hour, meeting the needs of small to medium-sized processing operations.

- Easy mobility: compact design with some models featuring casters for flexible movement to different work sites.

- Labor-saving: requires minimal manual operation, significantly reducing labor intensity and labor costs.

Components of portable peanut sheller

You can get a clear idea of the simple structure of the groundnut sheller machine by the presentation of the figure below.

Groundnut shell removing machine main structure

- Feed Unit: used to transport raw peanuts to the shelling area, commonly in the form of a conveyor belt or hopper.

- Shelling Mechanism: the core component of the equipment, typically consisting of a pair of rollers or blades, which remove the shells from the peanuts through friction or compression.

- Wind Separator: utilizes airflow principles to separate peanut shells from peanut kernels, ensuring thorough separation.

- Outfeed Unit: conveys shelled peanut kernels to the next process or collection container, commonly in the form of a conveyor belt or discharge chute.

- Control System: equipped with buttons, switches, or adjustment devices to control machine start/stop and parameter adjustments. Some models feature automated control systems to enhance operational convenience and efficiency.

Groundnut sheller machine working principle

Groundnut sheller machine works basically by removing the shell of the peanut through mechanical force and motion, which usually includes the following steps:

Infeed Stage

Raw-shelled peanuts are introduced into the shelling machine, usually using a conveyor belt or pallet.

Physical Separation

The peanuts are exposed to physical separation forces inside the groundnut sheller machine. This is usually accomplished by rotating drums, blades, or other shelling mechanisms.

Shelling Process

The peanuts are fed into the shelling mechanism and the shells are separated from the kernels. The key to this step is the design of the mechanism, which typically uses friction, vibration, or cutting to separate the shells.

Shell Separation

After shelling, the peanut kernels and the remaining shells are fed into an air separator or sifter. Here, through airflow or vibration, the lighter shell fragments are blown or screened out, while the heavier peanut kernels move on.

Discharge Stage

The shelled peanut kernels are conveyed to the discharge unit, usually via a conveyor belt or pipeline, for further processing or collection.

Technical data of groundnut sheller machine

The technical parameters of peanut shelling machines may vary depending on the manufacturer, model, and application, but the following are some common models for reference:

Model: TBH-200

Size: 650*560*1000mm

Production: 200KG/H

Power: gasoline engine 170/ motor/diesel engine 6 horsepower

At the same time, our company sells a large-scale combined peanut shelling unit, which realizes the cleaning and shelling of peanuts in one machine. You can specifically understand this equipment through: Industrial combined peanut groundnut shelling machine. Please feel free to contact us if you have any questions.