特徴の概要

機械は取り付け・操作が容易です。

ステンレス鋼材、耐腐食性。

1年以内の消耗部品を無料で提供します。

生涯にわたるオンライン技術サポートを提供します。

ゴマ皮むき機は、浸漬・攪拌・皮むき・分離を統合した高効率機器で、黒ゴマ・白ゴマなど食品加工分野で広く使用されています。

コンパクト設計と操作のしやすさにより、この装置はゴマ粒子の色を白く保ち、欠落率を95%以上超えることができます。80%-85%の皮むき率を実現し、食品加工工場・揚げ物工場などの理想的なゴマ加工機です。

ゴマ皮むき機の特徴のハイライト

- 縦型シリンダー設計、内部複合層構造(皮むき槽 洗浄槽)、従来装置の1/3の面積を占有します。

- 軸方向推進・放射状拡散・環状回転を組み合わせた複合攪拌機により、皮むき時のゴマに均一な力を加え、死角を残さず、皮むき率は80%以上に安定します。

- Integrated PLC制御パネル、浸漬時間(10-30分)、水流強度およびその他のパラメータが調整可能。

- 完成したゴマ核は白く明るく、ゴマペースト、ゴマ油、焼成材料などの高付加価値製品ラインに適しています。

- 循環水ろ過システムと負圧除塵装置を備え、水の使用量を約60%削減、粉塵排出 ≤ 10mg/m³。

ブラックゴマ脱殻機の構造と原理

- 複合攪拌機を回転させる減速機。

- 浸漬・攪拌・皮むきの過程を完了させる二重攪拌桶。

- 複合攪拌機:軸方向・放射状・輪状の回転を生み出し、皮むきの効率を向上させる。

- 分離スクリーニング板:ゴマの皮と種核の分離を実現します。

- 入口・出口:ゴマの循環・排出・皮・水を扱いやすくする。

- 浸し・洗浄工程で水量を管理するための水充填パイプラインシステム。

ゴマの皮むき機の作業手順

- 浸漬前処理:適量のアルカリ性水(または熱水)と混ぜ合わせたゴマを10-13分間浸します。

- 攪拌皮むき:浸漬したゴマを皮むき用のバケツに注ぎ、3-5分間高速で攪拌して皮をむく。

- 皮を核から分離する:分離ふるい板を使って種核を保持し、むけたゴマを取り除く。

- 洗浄槽に投入:バルブを通じてゴマを洗浄槽へ入り、水を約1/3投入する(ゴマ:水=3:1)、5-10分攪拌。

- 皮をむいた核を取り出す:底部排水弁を開き、水を流しながら皮を含む核を洗浄します。

- 排出収集:排出口を開いて排水後、処理済みのゴマ核を収集します。

ソースを作る際や油を絞る際には、ゴマの皮をむく必要はありません。食品産業で使用する場合は皮をむくべきです。

ゴマの殻むき機の技術パラメータ

| 機械名 | ゴマ脱殻機 |

| 電力 | 脱殻モーター 2.2kW, 分離モーター 1.5 kW |

| 容量 | 400-500kg/h 30-50kg/樽 |

| 脱殻率 | 80%-85% |

| 重量 | 500kg |

| サイズ | 1400*700*2000mm |

| 機械本体の材質 | ステンレス鋼製 |

ゴマの皮むき目的

ゴマは一般的な油生産では皮むきが行われない場合もありますが、直接消費されたり、さらなる加工に使用される場合には特に重要です。その理由は次のとおりです。

- ゴマの外皮には高食物繊維とシュウ酸塩が含まれており(約2%-3%のシュウ酸カルシウム複合体)、体内に吸収されにくい。

- むいたゴマは体内での消化・吸収がより容易になり、タンパク質とミネラルの利用率が高まります。

- むいたゴマは白色で、舌触りが細かく、味が良く、ゴマソース・ゴマペースト・菓子などの食品生産に適しています。

むいたゴマの広範な応用

むいたごまは応用範囲が広く、主に食品・飲食関連産業で使用されます。例えばパン、バーガー、ビスケット、シャキマ、タヒニ、ゴマ油、粉状の菓子など。

ゴマの皮むき機の設置とメンテナンス

設置要件:

- 初期設置時には、ゴマ皮むき機を水源・電源・排水設備の近くに設置してください。

- 水源に給水管を接続します。水圧が不足している場合はブースターポンプを設置してください。

- 電源を入れた後、機械が正常に作動しているかを確認します。

日常点検:

- ゴマ皮むき機の使用後は残渣を清掃し、機体をきれいに保ちます。

- 分離スクリーンの表面を水で洗浄し、詰まりがあれば高圧洗浄ガンで洗い流します。

- 減速機は円滑な作動を確保するため、潤滑油を定期的に交換する必要があります。

- 部品が摩耗していないか定期的に点検し、ブレードやメッシュなどの消耗部品を timely に交換します。

ゴマ清洗・皮むき機の他の用途

ゴマの皮むき機はカボチャの種子の皮むきにも使用できます。カボチャの皮むきの原理はゴマの皮むきと同じで、同じ機械が使用されます。

人によって異なる名称が付けられるだけです。中には彼をカボチャ種子の殻むき機と特に呼ぶ人もいます。ですから、カボチャがどのようにむかれるか、皮むきの効果を見てみましょう。

タンザニアへ販売されたゴマ皮むき機

私たちの顧客の一人はタンザニア出身です。彼はゴマ加工プラントを運営しており、皮をむかれたゴマをさまざまな食品加工業者に販売しています。

容量ニーズに基づき、ゴマ皮むき機を同時運転させる5台を提案します。梱包・出荷の写真は以下のとおりです。

このゴマ皮むき機についてご質問やご要望がありましたらお気軽にご連絡ください。迅速に回答し、すべての質問に丁寧に対応することをお約束します。皆様との協力を楽しみにしています!

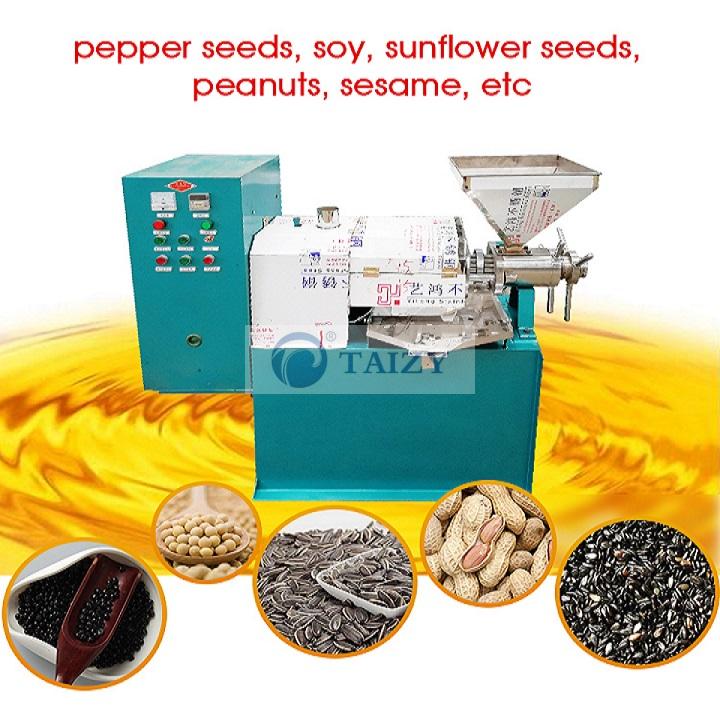

モデル:6YL-100

ねじ径(mm):Φ100

ねじ回転速度(r/min): 37

主電力(kw):7.5

容量(kg/h):150〜230

サイズ(mm):1900*1200*1300

モデル:6YZ-260

給餌径:260mm

加熱コイルの温度制御:70〜100

圧力:55Mpa

圧搾時間:10分

容量(1回あたり):10〜12kg

モデル: TZ-10

電力:5.5kW 1.5kW

容量: 300-400kg/h

サイズ:190*140*75cm